Many fly tyers spend hours each year developing new patterns. Half the fun is tinkering with the latest new synthetic materials, fluids and hairs. We all love the magic of developing a new pattern that we just can’t wait to try on the waters during trout season.

Many fly tyers spend hours each year developing new patterns. Half the fun is tinkering with the latest new synthetic materials, fluids and hairs. We all love the magic of developing a new pattern that we just can’t wait to try on the waters during trout season.

‘Flexament’ or ‘Flex-Seal’ are brand names for a special fluid used to coat feathers and other fly tying materials. When applied, it provides a flexible, durable coating that aids in preventing feathers from shredding. The brand names cost on average of $5-6 per one ounce bottle and usually with an extra charge added on for shipping and handling. There is an alternative to bringing the cost down. A little knowledge of basic ‘hardware store chemistry’ is all that is needed to get started.

Let’s talk about how to make your own ‘home brewed’ variety of a flex-cement. It becomes very economical if you use a lot of it; especially if you tie with a club, or group of tyers, where everyone can help to share in the expense of the hardware store chemicals.

From a local hardware store, pick up a tube of “Amazing Goop.” I used the original but any of their formulas will work. The tube comes in different sizes. I picked up the 1 ounce size and paid $4.00. Next, I picked up a quart of toluene (it’s the smallest I could find) and paid $9.00.

From a local hardware store, pick up a tube of “Amazing Goop.” I used the original but any of their formulas will work. The tube comes in different sizes. I picked up the 1 ounce size and paid $4.00. Next, I picked up a quart of toluene (it’s the smallest I could find) and paid $9.00.

Use a small disposable, plastic mixing cup and a disposable mixing stick. I started out with a teaspoon of “Goop” and added about ½ teaspoon of toluene. Mix these together until the “Goop” is totally dissolved. This process only takes a couple of minutes. Adjust the viscosity (thickness) of the solution by simply adding more “Goop” to thicken or more toluene to thin. I prefer a solution about the thickness of maple syrup.

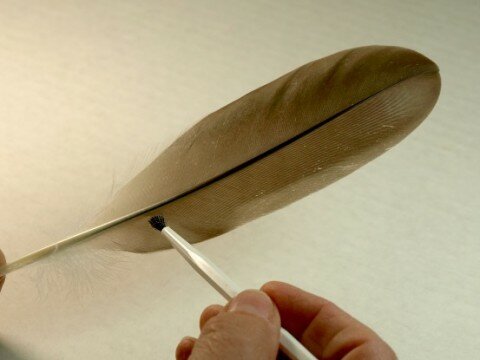

Once adjusted to the desired thickness, take a small paint brush and apply the fluid to a feather or other material. Once it has dried determine if it has achieved the desired effect. If needed, readjust the viscosity.

Once adjusted to the desired thickness, take a small paint brush and apply the fluid to a feather or other material. Once it has dried determine if it has achieved the desired effect. If needed, readjust the viscosity.

Once the correct per portion of Goop vs. toluene has been determined, mix up a larger quantity of the home made flex-cement. Once prepared, it can be stored in small glass bottles with tight sealing lids. At any time in the future if the fluid thickens, simply add a little more toluene to thin it out.

According to the company’s technical data sheet, “Goop” is made with toluene; that is the recommended thinner. It also states that it can be thinned with gasoline as well as other solvents. I never recommend the use of gasoline as a solvent for anything … I strongly suggest that you just stay with the toluene. When it comes to “Goop” and toluene be sure to read the precautions on the labels! In fact, when using any organic compound it is advisable to read all of the precautionary labels! Organic compounds and their vapors can be extremely dangerous!

The ‘commercial’ product arrives in a little 1oz. flint wide mouth square glass bottle with a polyseal cone lid. These bottles are available on the internet but only in large quantities. I suggest that you talk to a local pharmacist and see if they can assist with an alternative bottle.

The ‘commercial’ product arrives in a little 1oz. flint wide mouth square glass bottle with a polyseal cone lid. These bottles are available on the internet but only in large quantities. I suggest that you talk to a local pharmacist and see if they can assist with an alternative bottle.

The 1oz. tube of “Goop” mixed with the toluene, to the consistency I desired, yielded about 8 oz. of my homemade flex. The remaining toluene is enough to make an additional 24 1 oz. bottles.

Visit Tom’s website at www.michigandryflies.net